1. Luminance.Generally LED prices are different for different brightness, the higher brightness the higher price, people can choose LED according to their requirements.

2. Electrostatic discharge ( ESD),regular LED ESD is about 2000V, but sometimes customer will request higher ESD to prevent LED burn out due to unstable voltage during working.

3. Wavelength.You need to know whether the consistency of LED wavelength meet standards, generally the same wavelength LED, the same emitting color. But different factory chips in same wavelength, the emitting colors maybe a little difference. For example, some UV LED in wavelength 405nm, some LEDs emitting color would look tend to be blue, but some LEDs would look tend to be purple. So sometimes need to ask supplier to light up LEDs to show us the emitting light colors.

4. Safety features. The safety performance determines LED lifespan, normal LED lens is epoxy resin, but there are some LEDs which with anti-ultraviolet and fire retardant, the price is much higher, but the safety is also much higher, especially for outdoor application.

Standard operation is also one of the most important feature to impact LED lifespan.

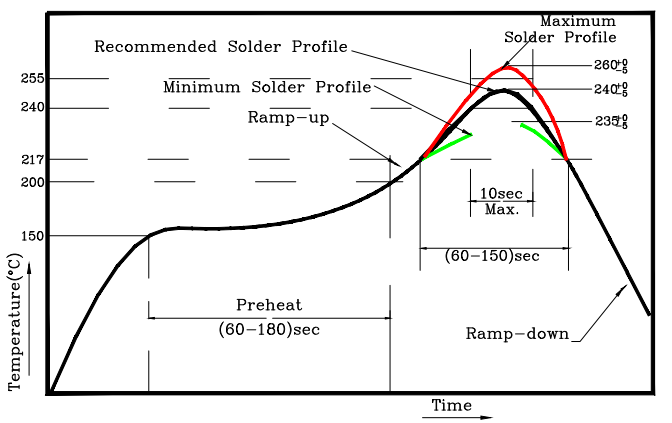

Soldering conditions

1. Iron soldering

A soldering iron is generally request less 20w, max. 30w under 260℃and less than 3 seconds.

2. Soldering

Soldering Max. Temperature 260℃, soldering time less 5 seconds. Do not touch the lens at high temperature. And do not force on the lens and bend PCB after soldering.

Parts cleaning

Cleaning process after soldering

1. use freon TF or alcohol for cleaning.

2. Temperature of cleaning can not too high, need to control it at Max.50℃with 30 seconds or Max.30℃with 3 minutes.

3. Use ultrasound cleaning, the Max. Output power is 300w.

Note: when use chemicals to clean lens, need to pay attention that trichloroethylene, acetone will cause damage of lens. We can wipe and soak the LED lens with ethanol, but should be less 3 minutes.

Installation method

1. Pay attention on polarity position

2. Do not close to heating elements

3. Do not solder LED when PCB out deformed.

4. Use sleeve when solder LED

5. Do not force on LED when temperature return normal temperature.

Temperature characteristic

The LED lens (epoxy resin) is very fragile and easy broke if it is forced under high temperature.

According to LED temperature characteristic, temperature increase 5°C, light beam will decline 3%. So when use LED in summer, need to pay attention to the operating temperature and storage temperature.

1. Operating temperature for LED lamp Min. 25°Cand Max. 85°C. Storage temperature Min. -40°Cand Max. 100°C.

2. Operating temperature for LED display Min. 20°Cand Max. 70°C. Storage temperature Min.- 20°Cand Max. 85°C.

3. Operating temperature for outdoor LED Min. 20°Cand Max. 60°C. Storage temperature Min. -20°Cand Max. 70°C.

Voltage and current

1. Not recommend parallel application program, because it’s hard to keep working voltage the same is the working current is inequable .

2. Super bright white LED need to install a anti-static device, if the white LED damaged by static, will reduce the lifespan .

3. If LED operating voltage change 0.1v, operating current will change about 20mA. Generally, even use DC fault current limiter, still can make it dynamic pressure limiting voltage and current by using simple constant voltage circuit, to avoid LED damage.

4. Generally LED peak current is about 50-100mA. Reverse voltage is 5v, so when LED is working, need to notice design circuit can not over Max. voltage and current, or it’s will cause LED damage.

上一条: The differences between IR LED 850nm and 940nm

下一条: How does UV mosquito killer lamp work